What happens when cam phasers go bad? Around 5% of fatal accidents happened in past years due to cam phaser failures. Bad cam phasers can severely damage the solenoids, ECU, and prominently the engine.

You’re driving down the street, and all of a sudden, your engine light pops on. You’re nervous, you’re not sure why it popped on, but you don’t want to take any chances. You get it checked out, and it turns out your cam phasers went bad. Are you experiencing this issue? Do you need to know if you have a problem with your cam phasers? You want to know how to diagnose and fix the problem? Then read on.

The statistics of camshaft phaser that get bad are high. According to a study conducted by the National Highway Traffic Safety Administration, cam phasers get bad at a rate of 40% per year. The study is conducted on cam phasers from the year 2010 to 2019.

I’m going to show you how to diagnose these cam phasers and fix them yourself. Relax, enjoy and learn!

Don’t forget to check the engine coolant level regularly. Here’s my guide on how to dodge expensive repairs. Here’s what you need to know about Best F150 Seat Covers. And here’s my guide to Best Floor Mats For F150.

Read what does S mean on a car here.

Is your car in the garage? Here’s how to get a free courtesy car to drive around. Here’s my top pick motor oil for the Ford EcoBoost cyclone engine.

What Happens When Cam Phasers Go Bad In An Engine?

When a cam phaser goes bad, the Variable Control Timing (VCT) solenoids would be destroyed, and the engine control unit (ECU) would no longer be able to control the phasers. When this happens, the engine’s timing would be affected and could lead to excessive phaser noise.

This excessive phaser noise could be a result of lubrication issues. If not attended to, it can lead to valve timing problems which would eventually damage the engine.

Cam phaser accounts for about 35% of the engine failures. A study by a company called “Faster, Cheaper, Better” found that the number of cam phasers that get fixed every year is a lot because cam phasers break a lot.

When a cam phaser goes bad, the Variable Control Timing (VCT) solenoids would be destroyed, and the engine control unit (ECU) would no longer be able to control the phasers. When this happens, the engine’s timing would be affected and could lead to excessive phaser noise. I had great success by installing a cam phaser lockout kit for fixing engine click noise.

The latest study from the National Highway Traffic Safety Administration (NHTSA) tells us that a cam phaser problem causes 1 in 7 accidents with auto-braking systems. The study found a 5% chance of an accident when a cam phaser is not working. In the same survey, in the case of a cam phaser failure, an accident’s risk is doubled.

What Is A Cam Phaser

A cam phaser is a computer-operated sprocket attached to the camshaft, mounted on the cam drive sprocket, which controls the camshaft. The cam phaser’s primary duty is to adjust the camshaft’s position relative to the crankshaft and the pistons connected to it while the engine is running.

Asking what a camshaft is? Being an important aspect of the internal combustion engine (ICE), the camshaft can be identified by a cylindrical rod or shaft, with cam lobes in a tear-drop shape positioned along its length.

The camshaft controls the appropriate opening and closing timing of the intake and exhaust valves beneath it during the piston stroke, with the carefully calibrated lobes. For engine noise, you don’t have to knock down the entire engine if you installed an affordable cam phaser lockout kit.

How Do Cam Phasers Work

A cam phaser works with the camshaft to control valve timing. Valve timing is the opening and closing of the valves while the engine is running.

The cam phasers in a modern vehicle are located on the intake and exhaust cam sprockets and connected through a timing chain.

Cam phasers position the camshaft relative to the crankshaft, which is operated by a computer-controlled servo.

Cam phasers rotate the camshaft slightly fore or aft to advance or retard the valve timing to suit the engine needs. Advancing the valve timing at low rpm (revolutions per minute) would enhance drivability and throttle response. Retarding the valve timing when the engine is under load at high rpm reduces NOx emissions and improves fuel economy.

Read how to wash car seat covers here.

Reasons Why A Cam Phaser Goes Bad

Low Oil Pressure

Adequate oil pressure delivers power to the cam phaser at an exact time. When this is lacking, your cam phaser might go bad. This problem could also arise from a failed oil pump or dirty oil used. Also, the cam phasers are made of metals. Wearing the inside phasers caused by lack of oil pressure might lead to poor efficiency performance of the oil and might cause your cam phaser to go bad. Find out why your engine oil pressure is low at idle speed here.

Poor Oil Viscosity

Using the right oil for your cam phaser is necessary for friction reduction and the engine’s efficient running because the engine runs at a very high temperature. The right oil guarantees that proper viscosity is generated for adequate oil pressure. Using the wrong oil viscosity can cause the cam phasers to respond slowly, thereby damaging it. Don’t use confuse one oil grade with other by understanding the differences here.

Debris and Sludge

The presence of debris or dirt will affect oil flow and might cause your cam phaser to go bad. I use engine oil additives to keep my car running smoothly.

Not Changing the Oil Often

Always change the engine oil after a certain time to avoid cam phaser damage. Decide on the right oil before choosing one or either brand of the same grade oil. My comparison case study of Castrol and Pennzoil here. Always clean your engine oil system between oil changes with a specialized engine flush for improved performance.

Damaged Sprocket or Gear

A damaged or worn-out sprocket or gear can be a reason your cam phaser got spoilt. Friction modifiers are recommended for reducing wear.

Problems within the Electrical Control Unit

Then ECU controls the cam phaser, and once the computer lacks control of the cam phaser, your cam phaser might go bad. Obd2 readers can come in handy for diagnosing ECU problems. You should get a manual for your car repair too, so you don’t get ripped at the garage.

Bad Cam Phaser Symptoms

Cam Phaser Noise

Hearing the sound of a loud engine click noise might signify that your cam phaser is bad. The cam phaser noise is, as a result, low oil pressure due to wear in the cam sprocket in the cylinder heads. Cam phaser lockout kit is a perfect solution for engine click noise. Read the pros and cons of cam phaser lockout kit here.

Decreased fuel economy

Lousy gas mileage would be noticed. Having an eco graph meter installed can help you monitor, compare and improve your mileage.

Check Engine Light Illuminated

When a cam phaser goes bad, the ECU will try its best to protect the engine. It would go into a limp mode and prevent the engine from exceeding a certain rpm. Then, the ECU would throw an OBD2 code, and the check engine light would come on. You’ll need a obd card reader and a manual for your model to read the ECU trouble code.

Loss of engine power

If you experience a noticeable loss of engine power, you probably have a bad cam phaser. For example, the engine can’t accelerate past 40rpm.

Poor engine performance

If you notice poor engine performance such as hard starting, misfiring, irregular acceleration, it’s a signal that you have a bad cam phaser.

Bad Camshaft Symptoms

- Car runs rough

- Car lacks power with sudden surges when flooring the gas at around 50 and 60 MPH. Fails to reach its top speed.

- Hard starting or stalling

- Car fails to start at all

- Car runs poorly when cold and improves with warm up time

- Rough idling and stalling at idle

- Car vibrates when accelerating or under load

- Car overheats

Diagnosing a Bad Cam Phaser

An in-depth understanding of what the potential problems could be would be of help in failed cam phaser diagnosis. The problems could be mechanical, electrical, or hydraulic problems. Mechanical problems could be stuck vane, stretched, or slack timing chains. Electrical problems could be failed camshaft timing sensors, failed solenoids, or other wiring issues. You need compatible readers to read electrical error codes. And repair manual to identify the issues. Hydraulic problems could be low oil level or pressure, poor oil viscosity, and oil supply restrictions.

Each of these areas should be tested to ascertain the root cause of failure. Various tools would be required to perform this diagnosis.

Step 1

A scan tool is first used for the cam phaser diagnosis. The scan tool would provide relevant OBD2 codes that would pinpoint exactly where the problem is and deliver other pertinent information to complete the problem.

Step 2

Check for correct oil pressure and viscosity in the engine using an oil pressure gauge.

Step 3

Inspect the filter screens on the oil control VCT solenoids and in the hydraulic passages.

Step 4

Inspect the electrical components and wirings for breach.

Cam Phaser Replacement Guide

You want to know how to replace your spoilt cam phasers, follow the Step by Step guide on cam phaser replacement below:

That fault code is a turning point. If repair costs are climbing and your current loan feels like it’s holding you back, this is the time to plan ahead. The free Car Loan Payment Tracker helps you see how quickly you can pay off what’s left—and start preparing, with confidence, for your dream car.

Step 1

Open your bonnet and disconnect the battery.

Step 2

Take out the air intake tube.

Step 3

You’ll find about three 10mm bolts on the power steering reservoir. Unbolt them.

Step 4

You’ll find one 18mm bolt and two 13mm bolts on the power steering reservoir bracket. Unbolt them.

Step 5

You’ll find the positive crankcase ventilation (PVC) tube on the valve cover. Remove it.

Step 6

Unplug the main wiring plugs and the electrical components on the driver’s side’s valve cover. It includes the cam position sensor, throttle control sensor, variable cam timing solenoid, fuel injectors, and coil packs.

Step 7

Unplug the power train control module and disconnect the mounting bracket.

Step 8

As you’re disconnecting the plugs, make sure you label them with tapes and markers for easy recoupling.

Step 9

Use capable air compressor to remove dirt from the valve cover, which is already exposed, to prevent dirt from entering into the valve-train while removing the cover.

Step 10

You’ll find 8mm cover bolts on the valve cover. Loosen them.

Step 11

You’ll find an 8mm bolt on the dipstick tube. Remove it without removing the dipstick tube itself.

Step 12

Disconnect the ignition coil packs and the cam timing solenoid.

Step 13

Carefully raise the cover off to prevent the variable cam timing solenoid from damaging.

Step 14

Bring out your timing chain wedge tool and insert it in between the chain’s two halves.

Step 15

Use a dowel pin to mark the cam phaser’s position with respect to the timing chain and the camshaft.

Step 16

Use vice grips and a bar breaker to loosen the cam phaser bolts.

Step 17

Remove the bolts on the cam phaser and gently remove the cam phaser from the camshaft while trying to remove the timing chain from the cam phaser sprocket.

Step 18

Insert the new cam phaser and use the dowel pin to properly align the new cam phaser using the old phaser as a reference during installation.

Step 19

Tighten the newly installed cam phaser bolts to a torque of about 30fts/Ibs.

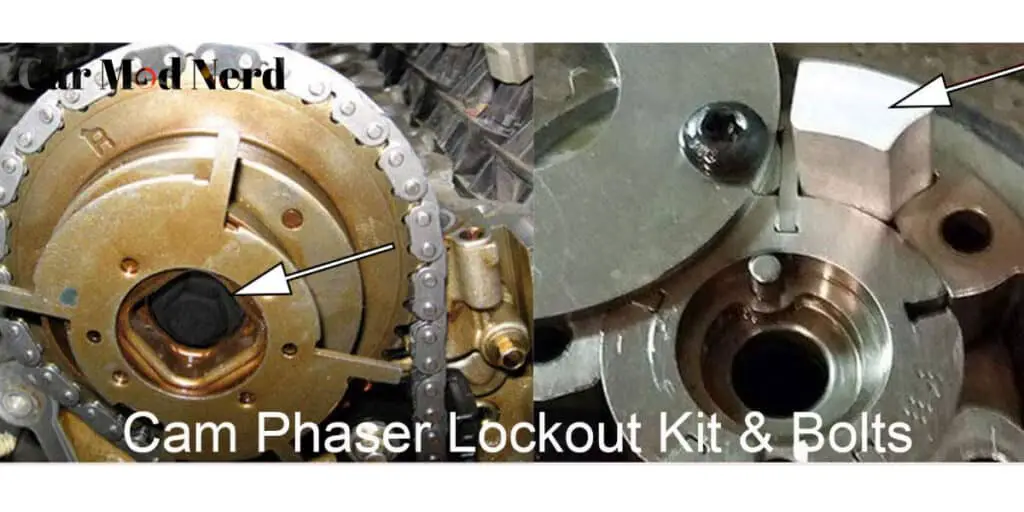

Alternatively, you can install a cam phaser lockout kit.

Cam Phaser Replacement Cost

Cam phaser replacement cost depends on the make, model, and year of the vehicle and ranges from $800 to $2500 including parts and labor. It may take up to one good week to go from getting an appointment to diagnosis and installation. Mechanics need to take down and diagnose it before making an estimate. This extra work adds up the cost and time. You better get the manual for your vehicle model and follow the diagnosis steps here and do your own inspection before taking it to a body shop. And if you have to, don’t forget to ask for your free loaner car while they work on yours.

How to Prevent Cam Phaser Failure

Here are some easy ways to prevent the cam phasers from failing:

Regular Oil Change

This would ensure that the appropriate amount of oil viscosity is supplied to the phasers for the engine’s smooth running.

Use the Right Engine Oil

Low oil pressure or a too-thin oil would lead to cam phaser failure.

Regular Filter Changes

This would help to prevent leakage of seals and solenoids in the phaser system. I always have an oil leak stop in case of emergency.

Regular Cleaning or Replacing The Solenoids

Over time, the solenoids also get gummed up with sludge, and this can contribute to the knocking sound. Cleaning or replacing the solenoids during maintenance would help prevent cam phaser failure. All purpose cleaners are helpful for cleaning solenoids and other parts.

Bad Cam Phaser FAQ

23% of all car owners who diagnosed and fixed their cam phaser problems in the last 12 months were surveyed:

- 24% of Toyota Camry owners

- 25% of Honda Accord owners

- 27% of Honda Civic owners

- 28% of Acura TL owners

- 29% of Nissan Altima owners and 33% of Acura TSX owners

Now you know what happens when cam phaser goes bad, how to diagnose, fix and prevent. I’ve seen a steady increase in cam phasers diagnoses and subsequent fixings. I’ve been a cam phaser diagnostic specialist for a couple of years now. I realize that the best method to solve cam phaser issues would be to lock the variable cam timing by essentially turning the phaser into a fixed timing gear using a phaser lockout kit.

Confused about your halogen headlight? Check out my latest blog here on H7 halogen headlight and don’t regret later, don’t miss the H1 headlight bulb post either. You can also learn when to use high and low beam here. Read how I measure my truck bed here and tips on how to keep luggage dry in truck bed.

My 2007 F-159 with the 5.4 motor sounds like birds chirping when under acceleration. My mechanic checked the serpentine

belt and it was not slipping on any of the pullies. He then thought the cam phaser on the drivers side was making the noise ????

Hi Craig,

There are many possibilities. It can be caused by low oil levels or improper lubrication. Also you should check the wheel bearing. Ideally a professional mechanic should run a thorough inspection and help you solve the problem.

keep me posted if you figure out the issue.

Thanks

Would Replacement of the VCT cause any problems with the Fuel rail pressure sensor, powertrain control module monitor, the fuel pressure regulator and vacuum engine leaks, problems and low fuel pressure.

It can be. Hard to tell without proper inspection

Hello! We have a 2018 Expedition with the Cam Shaft recall. They said the recall only fixes issues that haven’t happened yet, if you have the rattle already Ford doesn’t have a fix. All my readings say if it’s already and issue it’s causing damage. The Ford dealer shrugs their shoulders and says Ford doesn’t respond so ya. Warranty ends in 2 months, we want something out of this and they are just saying Ford doesn’t have anything so oh well. Any help?

Sorry to hear that. You can contact them directly. This might help: https://www.ford.com/cmslibs/content/dam/brand_ford/en_us/brand/resources/general/pdf/warranty/2018-Ford-Car-Lt-Truck-Warranty-version-3_frdwa_EN-US_08_2017.pdf

Please keep me updated.

My 2004 Ford F150 is currently at the ford dealership. They discovered that the cam phasers were stuck. When we experienced the vehicle running extremely rough we had it towed to the dealership, so we did not drive the truck under those conditions long. They are recommending that the mechanic take the entire engine apart because they say that may not be the only problem and if they replace them they might go bad again, but so far that is the only problem they have found (not done tearing it down yet). I was told today that the mechanic is recommending I replace the engine. ( I asked for a quote for a new engine because the sales rep told me that tearing the engine down could determine if it should be replaced or could be fixed) This does not sound right to me since this seems to be a fixable problem. I fear they are going to come up with a ton of other stuff that they need to fix or replace so that I am encouraged to just replace it. help

Hi Theresa,

Sorry for delayed response. Replacing the whole engine can be costly. You may contact with another independent mechanic to inspect your vehicle. It’s really hard to recommend for unique cases like yours without a physical inspection. Best wishes.

Ford let us down on this . I have complained since 10,000 miles mine was rattling on start up was horrible . I used synthetic oil like it says dealer changed oil said use better grade gas did that never fixed it . Dealer said they don’t know til Ford tells them 40,000 miles later Ford has FSA come out to repair this is a major repair . Now my engine runs rough after being done tho it does not rattle and reverse shift out really hard . Very disappointed

Which oil did you use? Here’s my post on best oil for ford: https://carmodnerd.com/best-oil-for-3-5-ecoboost/

Also, did you try cam phaser lockout kit? Here’s my guide on that: https://carmodnerd.com/cam-phaser-lockout-pros-and-cons/

Great article. The best I’ve ever read in regards to stating a problem part, describing what the part is, explaining what the part does, providing detailed directions on what and how and why to replace any and all parts necessary and possibly also necessary for optimal performance for any vehicle. I have always been very particular on what words I use when I speak or write, because words matter. Good words and proper delivery are what make the difference between hearing or reading something and being able to understand what is being expressed, and ya no da uthr dreded waay sum pepl git wrds 2 flo frum der yapper n tryin 2 git wut de textn ta mak cents. Yanowa I’m saying, Holmes?.

Lol thank you for the great information, I’m trying to diagnose my friends Expedition, who is actually a mechanic by trade. There are so many things going foul in his engine, it’s crazy. And it just caught fire at the head because of a spark plug blow out, so it’s time to get it fixed!

Thanks a lot for your kind words and really glad I could be of help.

The dealership will 100% bla I’m the owner for VVT failure,period! That said it’s not the German Fuchs oil you changed with every 5 k miles or wix filters used. Although they will tell you it’s all your fault. Truth is it is a very poorly engineered system, cam magnets will pop up but usually phasers and the rotating valve assembly is the reason. Boy are they fun to beat on when their newish, but 17000 for head work is excessive and that’s from a friendly shop. Gone are the. Days of reliable racy cars. Also Maclaren or Ferrari are also pricy to work on once you beat it like you stole it. Fun times but limited fun time frame. .back in the day yes gray hair, the b21 f engine Volvo had shimmed valves that if you were patient til 300o rpm it would run well for a 4 cylinder, and also never,NEVER AN ENGINE,HEAD TIMMING ISSUE OCCURED. That’s not to say work was never performed on that Volvo, but far and away RELIABLE, opposite bmw m4